In a recent exchange on Twitter, I was asked if I had any writing on procurement in the context of projects, as there is very little coverage about this topic for Project Managers.

Is procurement for projects different from other procurement?

There are opposing arguments, on the one hand that procurement for projects is very different from other procurement, on the other hand, that the ideal approaches to procurement are very similar whether for projects or not, and that the approaches become different only as one makes compromises. Such compromises would arise as a consequence of differences in objectives for projects and ‘business as usual’ (BAU), and from constraints in the capability of the procurement resource. Compromises may also be forced by late involvement of appropriate procurement expertise.

In my view, procurement maturity brings convergent practices (the timely use of a range of techniques from a comprehensive tool set) whereas immature procurement results in less refined and distinctly different approaches in response to the superficially different demands of projects and BAU. The different approaches may be driven by personal outlook, time constraints, and limitations in knowledge and technique. To be clear, I mean lack of experience and subtlety, not necessarily sophisticated or complex techniques. The key is in “superficially different demands” which, in the eyes of an experienced practitioner, may have rather more in common than might be apparent to the less experienced observer.

To explore the differences and similarities between the procurement requirements of projects and ‘business as usual’, it might help first to define the term ‘project’.

Definition of ‘Project’

The PMBOK Guide, 4th Edition defines a project as, “A temporary endeavor undertaken to create a unique product, service, or result.” The Guide elaborates, “Temporary does not necessarily mean short in duration. Temporary does not generally apply to the product, service or result created by the project; most projects are undertaken to create a lasting outcome…. An ongoing work effort is generally a repetitive process…. In contrast, because of the unique nature of projects there may be uncertainties about the products, services or results that the project creates.”

A naive approach might consider the project as a finite entity, and for procurement to be concerned only with the project requirements (i.e. in-project consumables and project deliverables). A more considered approach might take account of the lasting outcome and, in doing so, reflect on the synergy and conflicts between the project requirements and the lasting outcome. This may lead to benefits for both the project and the outcome. However, consideration of the lasting outcome may be outside the scope of the project. Then, arguably, a procurement view would be relevant at project definition, when the project scope is determined.

For the moment, let us take the simple view that project procurement and other procurement is different, or more appropriately, that procurement for projects is a sub-set of procurement in general.

Purchasing styles and techniques

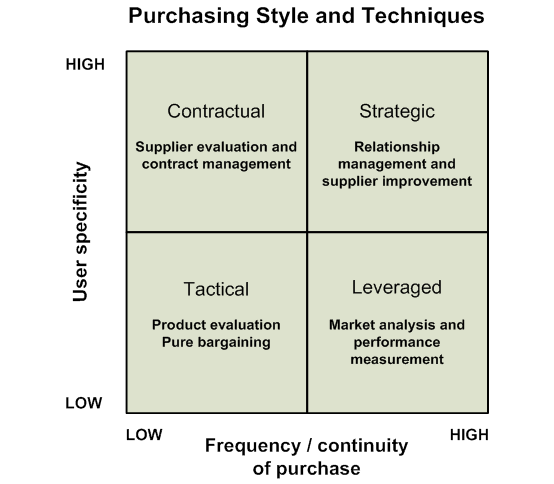

Figure 1 sets out different purchasing styles and techniques for the four quadrants of a 2×2 matrix. On the vertical axis is user-specificity – i.e. the uniqueness and customer-specific nature of the requirement – on the horizontal axis is the repetitiveness or continuity of requirement.

The unique and customer-specific nature of a project, combined with its temporary nature places the project (as a single entity) within the upper left quadrant of the matrix. This implies the approach to achieve best outcomes might be to formally manage the contract cycle – for example, detailed specifications, supplier qualification, invitations to tender, bid evaluation and negotiations, drafting of agreements – which sits comfortably with formal project management methodology. Advocates of agile project management may well be looking for a more dynamic approach.

If one was to procure the delivery of the project as a turnkey solution then the ‘contractual’ quadrant would apply. In breaking down the project, however, there will be a range of requirements, potentially from all four quadrants of the matrix. For example, a building project may have requirements for electrical installation (contractual), design and assurance services (strategic), labour (leveraged), and electrical fittings (tactical). The longer the duration of a project, the more likely that there will be either repeating or continuing requirements. So, even without considering the project outcomes, a project may need the range of approaches and techniques that apply to general procurement.

The relevance of alternative procurement practices

The simplistic view might still be that the preferred skills and experience for project procurement is centred around the contractual quadrant. But techniques used in other quadrants, and necessary skills, have a more subtle relevance. Take, as an example, the ‘leveraged’ quadrant diagonally opposite.

Repetitive purchases of commodity or producer-specified goods/services can often be managed effectively by tracking the relative value of goods/services in the marketplace and the performance of the supplier, and by using ‘Chinese contracts’.

A ‘Chinese contract’ is an agreement for which outside enforcement is unnecessary because the self-interest of the parties is sufficient for each party to achieve a satisfactory outcome. Leverage of either party over the other derives from future benefit or (economic) utility that the other party stands to lose. The power in the relationship does not necessarily have to be balanced, as long as the benefits to the submissive party outweigh the disadvantages of being dominated. Chinese contracts work well where there is

(a) continuing, or repetitive, requirement and supply – a relationship, not a single transaction,

(b) where the specifications are defined and unambiguous – avoiding ‘this isn’t what you said you wanted/would deliver’, and

(c) each party is clear as to the utility it will gain – each knows ‘what is in it for us’.

It might seem that Chinese contracts have little application in for a complex, unique, highly customer-specified requirement. The applicability is not in the ‘contract’ itself but in the thought processes (and the skill) in setting one up.

The self-enforcing nature is reliant on the interdependency of the desired outcomes for each party. For the deal to be effective, one-sided dependency – the possibility of a ‘lock-in’ – has to be minimal. Also, there has to be surplus value (value to buyer exceeding cost of supply) shared between the parties, otherwise the disadvantaged party will go elsewhere. The point is that either party can leave when the deal turns into something that doesn’t make commercial sense. But trapping one party in any deal that doesn’t make commercial sense invariably means a bad outcome for the other party.

Too much legal focus is on adversarial self-protection – on risk transfer and creating ‘a stick’ to beat the other party – not enough on structuring a deal that will be sustainable and maximise surplus value. No matter how comprehensive and detailed the formal agreement, when a deal goes bad both parties suffer. The disadvantaged party turns to protecting its own interests rather than necessarily fulfilling its obligations. This is not an argument against formal agreements; it is an argument to have self-sustaining mechanisms within the deal.

Deals constructed for the early benefit of one party and the later benefit for the other – as is often the case with projects – are particularly susceptible to lock-in and exploitation. There are many public sector examples – failed ICT projects, PFI/PPP infrastructure projects and Defence systems with ongoing maintenance – where the contracts have failed to achieve a healthy balance in value creation for the buyer and the value appropriation by the supplier. Controls need to be symmetrical; buyer and supplier interest cycles and utility need to be synchronized. A simple example is staged payments, but much more creative approaches are needed in complex projects. The principles applied within the leveraged and strategic quadrants of Figure 1 have much to offer. I am not going into further details here but readers who are interested may wish to read an earlier article, Three Principles for Effective Services Contracting.

I opened with the question, ” Is procurement for projects different from other procurement? ” In highlighting the diversity of requirements within many projects, and the relevance of some techniques from informal repetitive arrangements, I hope I have at least opened the case that procurement for projects has much in common with other mature procurement practice.

Related Articles:

- Procurement for Projects: Supply Planning (Part 1)

- Procurement for Projects: Supply Planning (Part 2) – 3 Key Elements; 6 Tools & Techniques

- Three Principles for Effective Services Contracting

- How to select suppliers to create value (Introduction)

- How to select suppliers to create value: Supplier Appraisal