This blog is inspired by Rudi Verheyden who posted a question “Does Supply Chain LEANness mean that the Supply Chain organisation is also agile, or are these 2 elements rather conflicting or independent from each other ?” in the Supply Chain Optimization Group on LinkedIn. (The same question is also posted in the Inspired Supply Chain & Logistics Executives Group but at time of writing had no comments.)

This is a very big question, with many facets to be explored. I look forward to following the discussion. My immediate thoughts are that there is some conflict, some consistency and some dependency.

If we look to the origins and most extensive applications of ‘lean’ – Toyota, and manufacturing assembly operations, respectively – two approaches emerged: the more generally applied approach prioritises the elimination of muda (unproductive activity); the Toyota approach prioritises the elimination of mura (irregularity/unevenness) with the elimination of muda and muri (excess) as a consequence rather than the primary objective. The two approaches will have differences in their relationships with agility. For now, I will stick to the similarities (with the intention of returning to the differences as the discussion progresses).

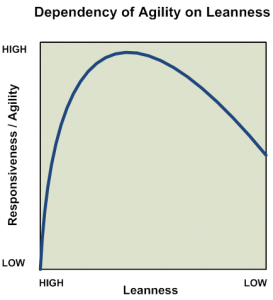

In both approaches, lean practice has transformed the downstream stages of the supply chain, scheduling according to demand pull, and generally increasing agility. The effect is to move the pull-push boundary, and stock holding, upstream in the supply chain. Responsiveness relies on the availability of resources to meet demand. Excess stock in the supply chain, and the practice of increasing batch size to create efficiencies, are directly in conflict with responsiveness. This might suggest a correlation between lean and agile. But there comes a point at which lack of resources, be they materials, manpower or machinery, limits a supply chain’s ability to respond. The relationship between lean and responsiveness becomes inverted. It follows that responsiveness (and agility) may have a dependency on leanness, as depicted in Figure 1.

At this point I am not going to comment on whether the terms ‘responsiveness’ and ‘agility’ are fully interchangeable, or how we might measure agility and leanness. Nor am I going to comment in detail on my interpretation of ‘lean’ . But fundamental questions that we need to address are, “What do we mean by a lean supply chain?” and “How lean is ‘lean’?”

Lean can only equate to zero waste and zero non-value-adding (NVA) activity in a static environment. In any complex and dynamic environment the lean state requires some NVA activity. Why is this? Consider three questions:

- Is it possible to achieve best practice, zero NVA activity, zero waste without innovation and experimentation?

- Can all experiments and innovations be 100% successful?

- Can experimental and innovation failures be NVA/waste free?

If the answer to these questions is “No” – and in most real-life circumstances this would be a reasonable answer – then maintenance of a lean state demands some waste and NVA activity. “How lean is ‘lean’?” then becomes a matter of maximising return on investment in current NVA activity.

Whilst agility would appear to have a dependency on leanness, I have difficulty in convincing myself that the dependency is mutual. Lack of agility increases waste (muri and muda), but that is not quite the same as agility making the supply chain more lean. The problem is with respect to eliminating unevenness (mura). Agility is all about dealing with a change… change in dynamic environments… more dynamic than the originators of lean manufacturing envisaged (and, arguably, more than the average lean practitioner is likely to experience).

Moving away from manufacturing assembly operations – to process and service industries – the application of lean techniques have been less successful. My roots are in process industries and fmcg. In fmcg supply chains, responsiveness to unpredictable demand can be fundamental to business success. Optimum positioning of the pull-push boundary, and carrying appropriate levels of stock at the interface, are hugely important. I have written about this in a 2-part article entitled “A single, shared forecast for the business… so what’s the problem? ” (Follow link to Part 2 : Products at risk, and managing inbound supply.) Another factor that frequently gets overlooked, is that retailing is not driven entirely by consumer pull. Retailing is a complex combination of push and pull. And this is not just in-store: it applies also to on-line retailing.

I am conscious that readers may interpreted my stance as being somewhat anti-lean. My intention is not to detract from the importance of lean practices, but to highlight the scope of Rudi Verheyden’s question. As I commented at the outset, this is a very big question, with many facets to be explored. I look forward to following the discussion with interest, and I hope my readers will too!

Hello Tony,

I read your post with great enthusiasm and fully digested your thoughts.

I agree with all your positions on this discussion.

Your view about agility/responsiveness interchangeability is highly respectable.

In my view, agility (heavily dependent on Leanness) is a potential state (or status) while responsiveness is a possible measure the potential. When rapid changes bigger than contingency plans can accommodate begin to happen in an SC’ operating environment, it is responsiveness that determines the business outcome.

Let me point out though that under “steady state” condition, the Responsiveness/Agility v. Lean curve having reached an optimum should plateau and remain like that overtime rather than drop drastically as depicted by your diagram. However if sudden unplanned events do occur and thus shift the “push-pull” equilibrium position in the SC, the curve can nose-dive and hit the canvas. This is where Responsiveness (?Agility) can determine the continued existence or otherwise of an organization.

The 3 questions raised by you are germane to the discussion. The “No” answer proffered to the questions is correct. This is because the questions dovetail one-to-the-next-question. Staring from q2, answer is “No” because “Zero-Error Plan” is nowhere reasonable let alone achievable in operations!

Answer to q3 is also “No”, but the NAV’s and wastes generated by experimental/innovation failures are really not “wastes” since they contribute to the organization’s “Knowledge Pool” or Learning. and should be manageable by any good SC designed around “Fit-for-Purpose” rather than a so called world-class model.

All said, thumbs up for you Tony.

Utmost regards.

Hi Amos.

Thank you for your comments. I think we are not too far apart in our views. The one thing I think I need to explain is why I have responsiveness falling dramatically at maximum leanness. The difference in our views may be in our definitions of responsiveness and leanness. My position is based on the Toyota approach to lean, focusing on elimination of mura: the ultimate in leanness equates to zero inventory in the entire supply chain. If responsiveness is then measured by the speed in fulfilling an unforseen demand, the best possible response is determined by the composite lead time over the entire supply chain – which I am suggesting is much slower than would be the case in a low-leanness supply chain with surplus stocks at critical points. I used a simple (x-squared) curve for the diagram, which is not a very good representation, so I can accept a less dramatic fall off up to a point, but still falling away at extreme leanness.

In practice, I think the application of lean techniques is mostly about moving from the right of the diagram towards an optimum postion. The whereabouts of the optimum is an interesting question. If we schedule for lowest cost, highest quality or best service, we get different results. So the skills and expertise of the practioner come into play. For now, I’ll save any cautionary advice regarding the left part of the curve for the LI discussion (I hope you will continue your critique there), and perhaps I’ll develop the theme in a future blog.

Kind regards,

Tony